In today’s rapidly advancing technological landscape, reliable electrical connectivity is crucial across industries such as automotive, marine, aerospace, industrial automation, and renewable energy. Waterproof connectors play a vital role in ensuring uninterrupted performance, especially in harsh environments where exposure to moisture, dust, chemicals, and extreme temperatures is common. Manufacturers of waterproof connectors are continuously innovating to meet the growing demand for durable, high-performance solutions.

The Importance of Waterproof Connectors

Waterproof connectors are designed to prevent water ingress, which can cause short circuits, corrosion, and system failures. These connectors are essential for applications like:

Automotive & EV Systems – Ensuring safety in electric vehicles and outdoor automotive electronics.

Marine & Offshore Equipment – Withstanding saltwater exposure and humidity.

Industrial Machinery – Protecting connections in factories with high moisture or dust levels.

Renewable Energy Systems – Solar panels and wind turbines exposed to weather extremes.

Outdoor Telecommunications – Maintaining signal integrity in rain or extreme conditions.

Key Features of High-Quality Waterproof Connectors

Leading manufacturers focus on several critical aspects:

IP Ratings (Ingress Protection) – Connectors often meet IP67, IP68, or IP69K standards, ensuring resistance to water and dust.

Material Durability – High-grade plastics, rubber seals, and corrosion-resistant metals enhance longevity.

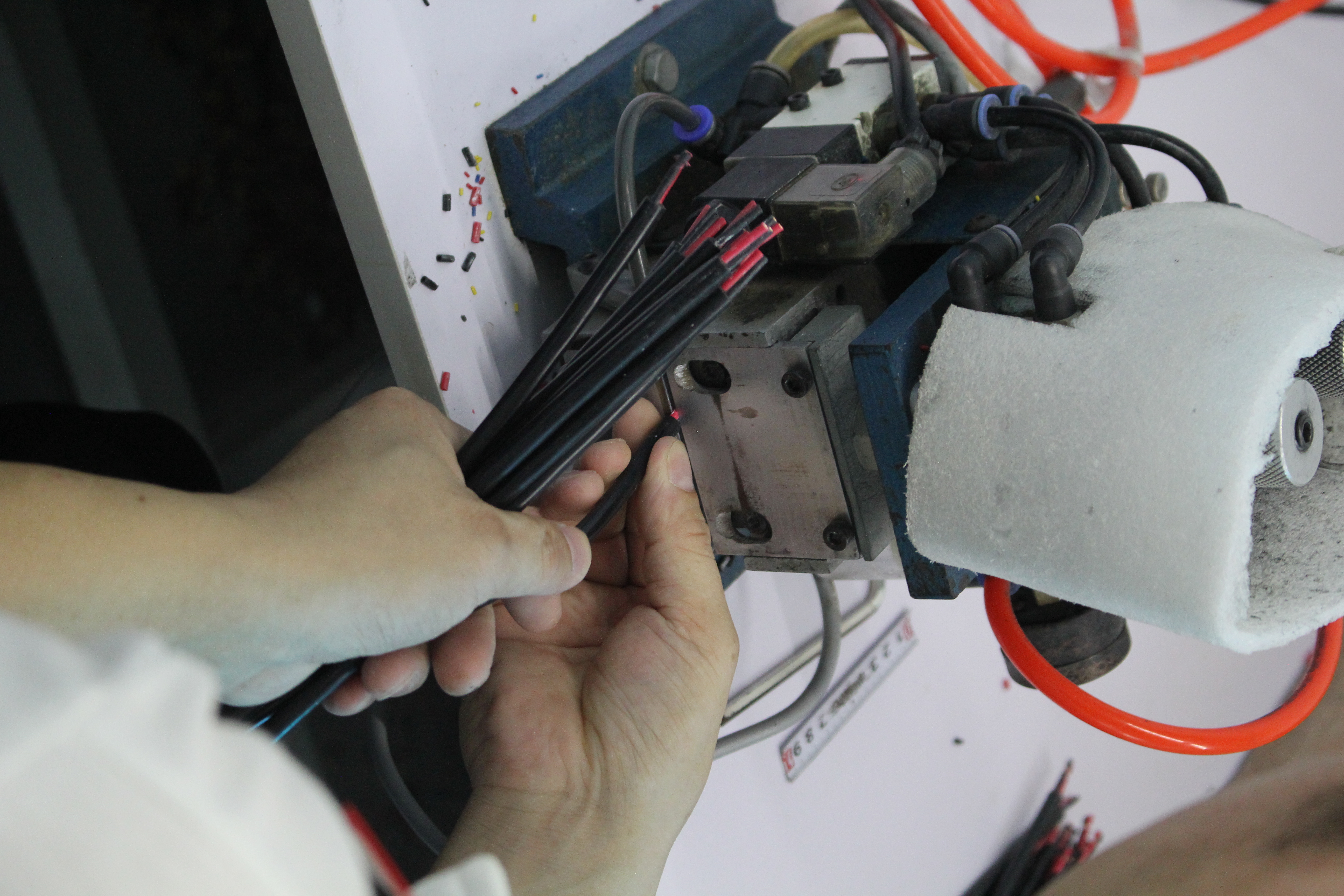

Secure Locking Mechanisms – Screw locks, push-pull designs, and bayonet couplings prevent accidental disconnections.

Temperature & Chemical Resistance – Reliable performance in extreme heat, cold, or corrosive environments.

Customization Options – Manufacturers offer tailored solutions for specific voltage, current, and size requirements.

Innovations in Waterproof Connector Manufacturing

To keep up with industry demands, manufacturers are integrating advanced technologies such as:

Miniaturization – Compact yet robust connectors for modern electronics.

Hybrid Connectors – Combining power, signal, and data transmission in a single waterproof unit.

Quick-Connect Systems – Reducing installation time while maintaining a secure seal.

Eco-Friendly Materials – Sustainable designs that comply with environmental regulations.

Choosing the Right Waterproof Connector Manufacturer

When selecting a supplier, consider:

✔ Industry Certifications (UL, IEC, ISO) ensuring compliance with safety standards.

✔ Proven Track Record in your specific application (e.g., automotive, military, or marine).

✔ Testing & Quality Control – Rigorous checks for waterproofing, vibration resistance, and durability.

✔ Global Support & Logistics – Availability of technical assistance and fast delivery.

Conclusion

Waterproof connector manufacturers are pivotal in enabling safe and efficient operations across multiple industries. By leveraging advanced engineering and stringent quality controls, they provide solutions that withstand the toughest conditions while ensuring seamless connectivity. As technology evolves, these manufacturers will continue to drive innovation, delivering even more robust and versatile connector systems for the future.