The demand for waterproof connectors continues to surge across industries such as automotive, marine, industrial automation, and consumer electronics. As technology evolves, connectors must adapt to harsher environments, higher data speeds, and stricter sustainability requirements. Below are the key trends shaping the future of waterproof connectors.

1. Miniaturization Without Compromising Performance

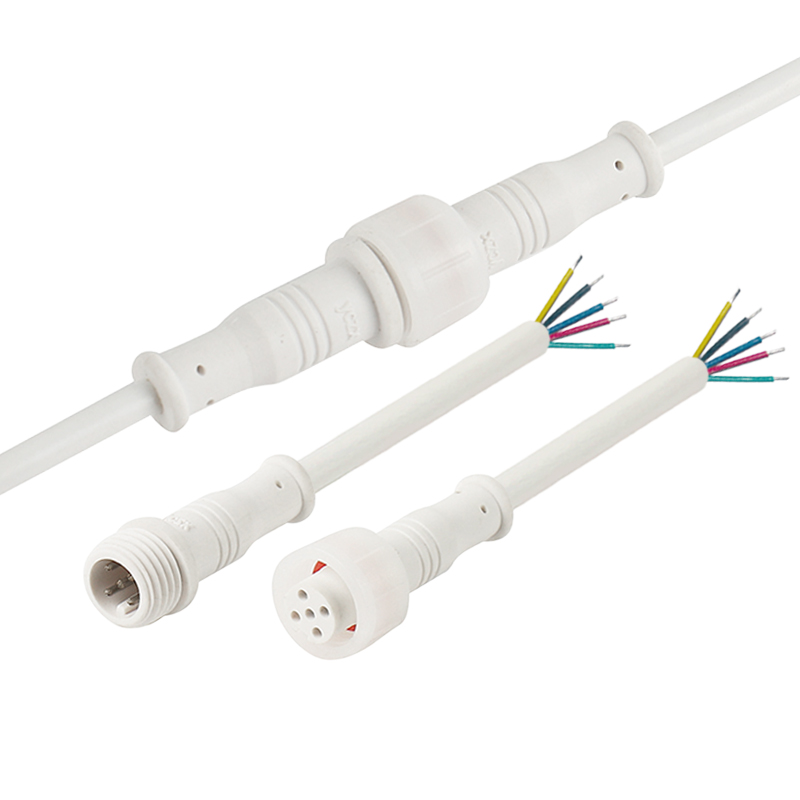

With the rise of compact IoT devices and wearables, manufacturers are developing smaller waterproof connectors (e.g., micro- and nano-connectors) that maintain IP68/IP69K ratings. Innovations in sealing technologies—like laser-welded housings and advanced gasket materials—enable high-density designs resistant to dust, moisture, and pressure.

2. Higher Data Transmission Capabilities

The shift to Industry 4.0 and 5G networks demands connectors that combine waterproofing with high-speed data transfer. New designs integrate shielding techniques to prevent EMI/RFI interference while supporting protocols like USB4, Ethernet CAT6A, and fiber optics. For example, underwater drones and autonomous vehicles now rely on waterproofed M12/M8 connectors with 10Gbps+ capabilities.

3. Robust Materials for Extreme Conditions

Traditional thermoplastics are being replaced by engineered polymers (e.g., PPS, PEEK) and corrosion-resistant metals (stainless steel, brass with nano-coatings). These materials endure extreme temperatures (−40°C to 125°C), UV exposure, and chemical corrosion, making them ideal for offshore energy, military, and aerospace applications.

4. Eco-Friendly and Sustainable Designs

Regulations like RoHS 3.0 and REACH push for halogen-free, recyclable materials. Companies are adopting biodegradable seals and lead-free plating. Additionally, modular designs allow repairs instead of replacements, reducing e-waste.

5. Smart Connectors with Embedded Sensors

The integration of IoT-enabled waterproof connectors with sensors (temperature, humidity, or vibration detection) enables predictive maintenance. For instance, in electric vehicle charging stations, smart connectors can alert users to seal degradation before leaks occur.

6. Simplified Installation and Modularity

Quick-lock mechanisms (e.g., push-pull or bayonet-style) reduce installation time, while field-attachable connectors simplify repairs in remote locations. This trend is critical for renewable energy systems like solar farms and underwater turbines.

Conclusion

The waterproof connector market is evolving toward smarter, greener, and more resilient solutions. As industries face stricter environmental and performance demands, innovation in materials, sealing tech, and connectivity will drive the next generation of waterproof interconnects.