Introduction

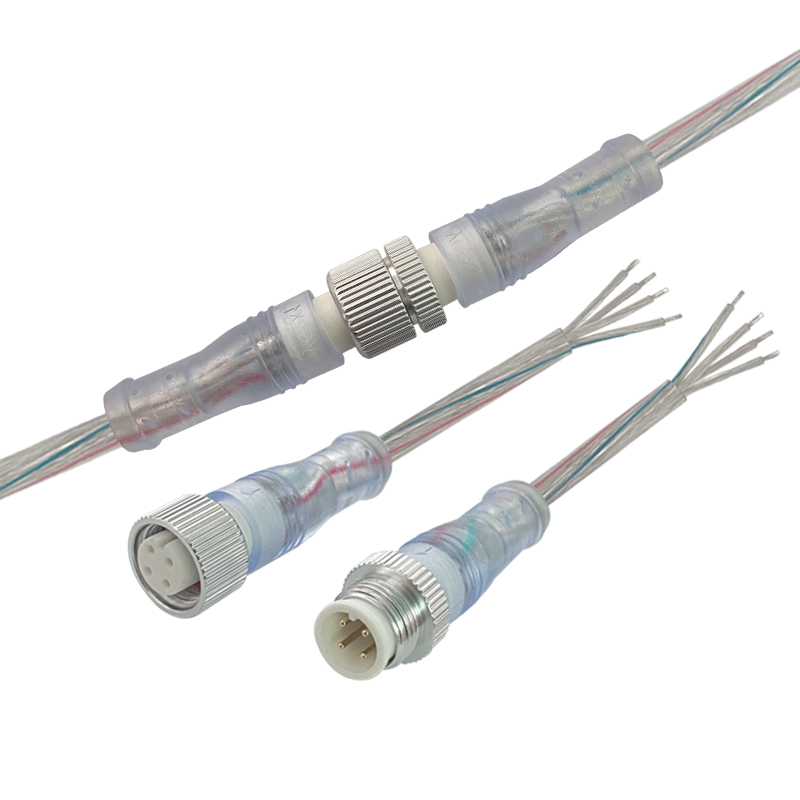

Importance of waterproof sealing in connectors for industrial, automotive, and marine applications.

Key factors: IP ratings, durability, cost, and assembly complexity.

1. O-Ring Seals

Principle: Elastic compression for water resistance.

Pros: Reusable, cost-effective, easy installation.

Cons: Limited to static applications, prone to extrusion.

Applications: Consumer electronics, automotive sensors.

2. Potting Compounds (Epoxy/Silicone)

Principle: Liquid resin fills cavities, then cures.

Pros: Superior sealing, vibration resistance, chemical protection.

Cons: Irreversible, adds weight, longer processing time.

Applications: Harsh environments (e.g., underwater cables).

3. Ultrasonic Welding

Principle: Melts plastic interfaces for hermetic bonds.

Pros: No added materials, high-speed assembly, strong seal.

Cons: Limited to thermoplastics, high equipment cost.

Applications: Medical devices, miniaturized connectors.

Comparison Table

| Method | IP Rating | Cost | Reusability | Best Use Case |

|---|---|---|---|---|

| O-Ring | IP67-68 | Low | Yes | Static, low-pressure |

| Potting | IP68-69K | Medium | No | Extreme environments |

| Ultrasonic Weld | IP68 | High | No | Precision plastic parts |

Conclusion

O-rings for cost-sensitive, reusable needs.

Potting for maximum protection in harsh conditions.

Ultrasonic welding for high-volume, plastic-based designs.